- Published on

Is Moore's Law Still Relevant?

- Authors

- Name

- Shashwat Kansal

- @shashwatkansal

Introduction

In 1965, Gordon Moore came up with a prediction that today is known by all industrialists in the semiconductor industry. He hypothesised that every two years, the number of transistors would double within an integrated chip (IC). For many industrialists this is a good target for the past 50 years or so, but today things are becoming a little tenser as companies are facing physical limits, and so they need to get ready for their plan B. Problem is: nobody is sure when exactly Moore's law is set to fail, or if it has already failed. You only have to type "Moore's Law" into Google to see what I'm talking about.

During the 1975 IEEE meeting (which forecasts the semiconductor industry and sets the guidelines) Moore explained that the forecast rate from 1980 would double every two years, for these reasons:

- Yields and profitability;

- Smaller dimensions of transistors;

- "circuit and device cleverness".

Yields mean that how many integrated circuits the semiconductor industry can produce without defects in the manufacturing process or difficulties. This would lead to how the industry can maintain maximum profitability and long-term sustainability. Minimum dimensions are directly related to, effectively, how many transistors can you fit on a board. Lastly, circuit cleverness refers to the functioning and design of the circuits boards, so effectively how efficient can this IC be made. If Moore's Law is to remain relevant today, we need to make sure that these three key points are still intact.

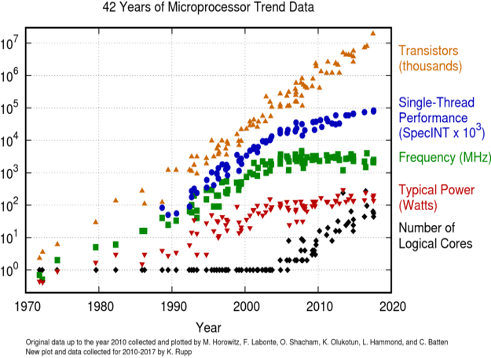

Rising Transistor Numbers

Taking data from 1996 to 2017 for several variables listed on the graph on the right versus year, with the latest data being July 2017, we can see that Moore's law is pretty much on track, giving us on average a very good linear line, with R2 value being 0.9504. This means that on a scale of 0-1, we can tell the linearity of two variables with 1 being 100% completely linear.

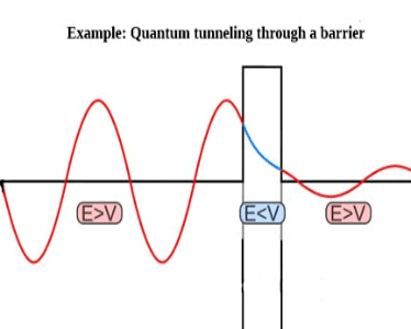

We can say this comfortably because the sizes of transistors are rapidly decreasing. Originally in the 80s, the common sizes of transistors were around 3mm2, and one could look at these through a kid's microscope toy. Today however, the current top industry standard is 10-20 nm. Whilst this shows great progress so far, the problem is that there is a physical limitation of around 7nm gate in a silicon-based transistor, which is what holds and controls the flows of electrons, essential to controlling flow of information. Any smaller than 7nm, then electrons are able to quantum tunnel. Because the gate thickness decreases, the electron is able to, in layman's terms, barrel right through them. This means that once you turn the transistor on, it will be extremely difficult to turn it off. This means that industry will struggle in the next few years to keep on adopting MOSFETs (metal-oxide semiconductor field effect transistor), if they plan to keep Moore's Law alive. In fact, companies such as Intel and Global Foundries have announced that after 2021, they will no longer reduce the sizes of transistors within the chips, casting a dim future for Moore's Law.

Yields and Financial Viability

Furthermore, we have Rock's law - commonly referred to Moore's second law - which helps to show that as cost of computing power falls, the cost for producers to fulfil Moore's law increases. This is because the cost of a semiconductor chip fabrication plant doubles about every four years, and hence directly collides with the Moore's first point, about yield and profitability. In 2015, fabrication plants have grown to a high of US$15 billion in cost, and out of the large number of companies that started in the semiconductor industry in the last quarter of the 20th century, only 4 remain: Intel, Global Foundries, Samsung and TSMC. For example, IBM recently sold their fabrication plant to Global Foundries for $1.5billion, as their chip manufacturing business was making heavy losses. This accentuates how capital-intensive the industry has become, and as a result is pressurising Moore's law, making it a tougher, much more expensive target to achieve.

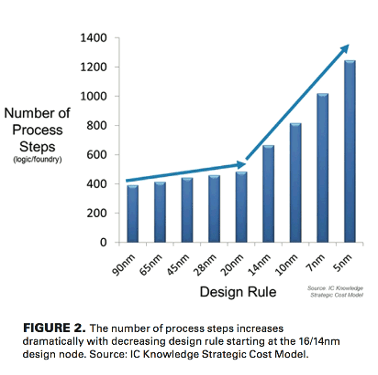

Moore's law has also been very accurate until now because the costs for manufacture of transistors has been relatively stable. However, as we hit 14-16nm small transistors, the process steps rapidly rise, due to increased complexity of the wafers. As a result, the number of problems rapidly rises because the defects within each chip are extremely tough to find. Even the smallest error in measurement or defect can render the entire chip to go to waste, meaning time is also wasted, as well as materials. New technologies such as 3D structures are difficult to integrate into existing models of chips, and so right now the only solution is to keep increasing the yield, which is a complicated process. It highlights that if Moore's Law is to stay relevant, companies will need to start adopting new techniques and look back at process controls and designs to improve their yield.

Techniques & Modifications

Whilst Moore's Law may still be on track for now, other factors such as clock speed have seen no growth even since 2005. Another rule called the Dennard scaling was an informal law stating that the smaller the transistors become, the less power they would use, hence reducing the heat that they would produce, allowing them to be packed closer. The fact that this law has completely broken down shows that perhaps one of the pillars of Moore's Law had broken down much earlier and could be another reason why Moore's law is losing its relevance. This is reflected in figure 4, which shows that the typical power and frequency of the transistors in total is seen to be plateauing since around 2005 – a strong sign that eventually simply making more and more transistors is not going to be very financially viable, efficient and progressive. This graph however says a lot more about strategies to keep Moore's law alive. With slight delay after 2005, the number of logical cores suddenly starts to rise to counter the plateauing of the typical power of the semiconductors. This shows that it is very possible that the power efficiency has hit a limit, and that the industrial leaders are finding alternative techniques to keep the performance of chips up. Cores are individual processing units, and to increase the processing power, instead of making more transistors in one CPU unit, more CPU units are made on the same unit/chip.

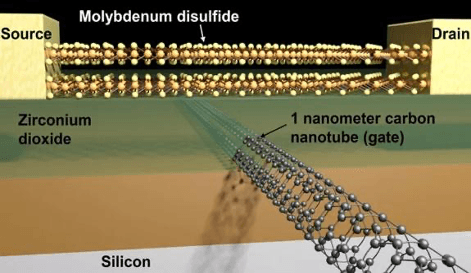

However, there is hope for continuity of Moore's law, as rapidly new techniques and combinations of compounds are being tested, moving away from SiO2 based MOSFETs. Whilst people were hyped about Intel's Cannonlake line bringing in 10nm long transistors, a team at Berkeley National Laboratory managed to build an astonishing functional 1nm transistor gate out of molybdenum disulphide! This incredible achievement means that there is hope yet for Moore's Law, and incredible new designs are being thought by experts of new chip designs, such as Samsung's 3D V-NAND Memory. NAND gates are the basic building block of transistors, and this new design ensures that its equivalent of NAND gates is 1000x faster than the ones used today.

Conclusion

All three of Moore's main reasons for exponential growth have been vastly broken: yields and profitability and rapidly declining; we are hitting limits to how small transistors can be; and we are compromising efficiency with simply how many transistors we can jam into a chip.

On the contrary, I believe this makes Moore's law all the more relevant today than before. For the past few decades, the usual strategy in industry was to increase the number of transistors overall. However now that we are on the brink of breaking Moore's law, it is evident that silicon is no longer the future, and in turn this has pressurised the industry into developing new techniques and experimenting with new compounds. Moore's law is important in bringing about this change of strategy for the industry, but I fear it will no longer remain relevant after we start using different compounds, because we will no longer focus on duplicating more and more transistors. A rough road lies ahead nonetheless, with increasingly rising financial instability and unpredictability in the upcoming future.